17 November 2025

By removing the need to move pallets from the palletiser to the wrapping station, PaceWrap significantly reduces cycle time and system footprint. The result is a fully integrated process that increases throughput, improves reliability, and simplifies installation in space-restricted production environments.

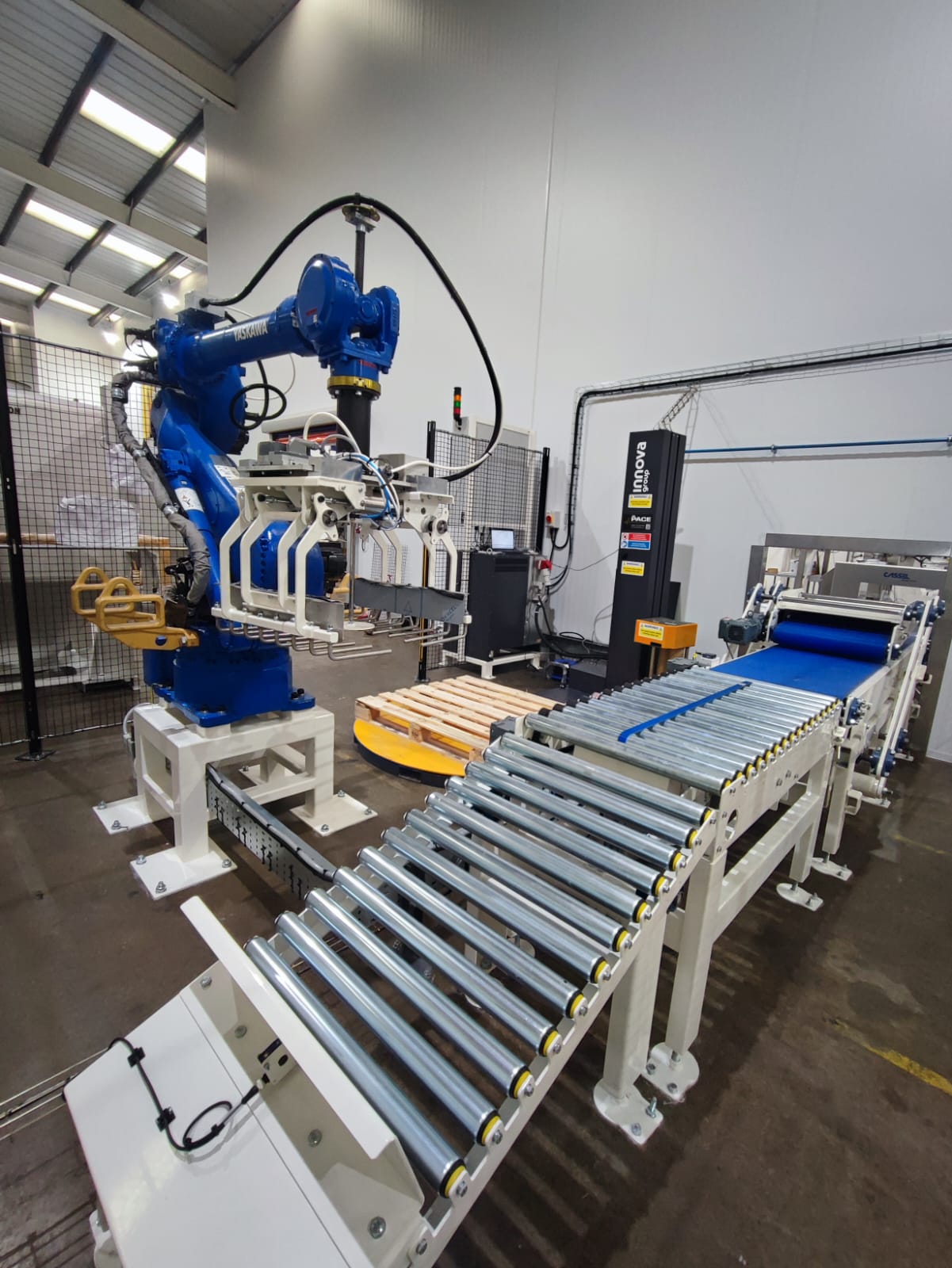

At the core of the system is the Motoman GP180-120 industrial robot, providing high payload capability, rapid cycle performance, and precise layer placement for a wide range of products and pallet configurations. The system is operated via an interactive 10” Inovance HMI, offering intuitive control, real-time diagnostics, guided workflows, and seamless recipe management.

Safety within the cell is managed using PILZ safety architecture, providing certified safe-motion control, guard interlocks, and robust operator protection.

A standout feature of PaceWrap is its AI-assisted robot training delivered directly through the PLC software. This allows pallet patterns and product recipes to be generated, modified, and deployed without relying on pendant-based teaching. Operators can create or adjust robot programs through the HMI, enabling fast changeovers, reduced commissioning time, and improved repeatability.

PaceWrap is now available for integration into new or existing production lines, with configuration options tailored to customer-specific product types, speeds, and facility layouts.